Why carbonfiber?

Carbon fiber is mainly chosen for weight reasons. Less weight is less energy waste. Carbon fiber is also a sturdy material which can withstand impacts from several directions. Glass fiber is also an option because it is more cost effective. However, glass fibres density is more than twice the density of carbon fibres and therfore signiciantly heavier.

Carbon fiber is one of the most wonderful materials we use for our solar car. It is a material of quite extraordinary properties that has led to be one of our most favored materials used to sculpt our prodigious Viking.

When constructing a race car which is going to travel thousands of kilometers through the vast spaces of Australia, you will need only the best materials available. Materials that are strong, for rigidity but also materials that are light weight enough for optimized performance.

Carbon fiber is the tremendous material that takes the quantum leap to qualify best when analyzing the criteria. It is a material of both great rigidity, but also low weight. This goes hand in hand with our values, at the same time, carbon fiber allows us to shape and form the parts in any way we desire. Such as an aerodynamically optimized vehicle.

On top of being strong and light weight, carbon fiber is also high in chemical resistance, is temperature tolerant at excessive heat but also has a low thermal expansion. This benefits us under the scorching sun in the outback of Australia.

Other examples of what carbon fiber is used for is: aeroplane wings, bike frames and propeller blades. These are all products that demand materials with low weight to strength ratio.

This is how it's done - see Johan in action

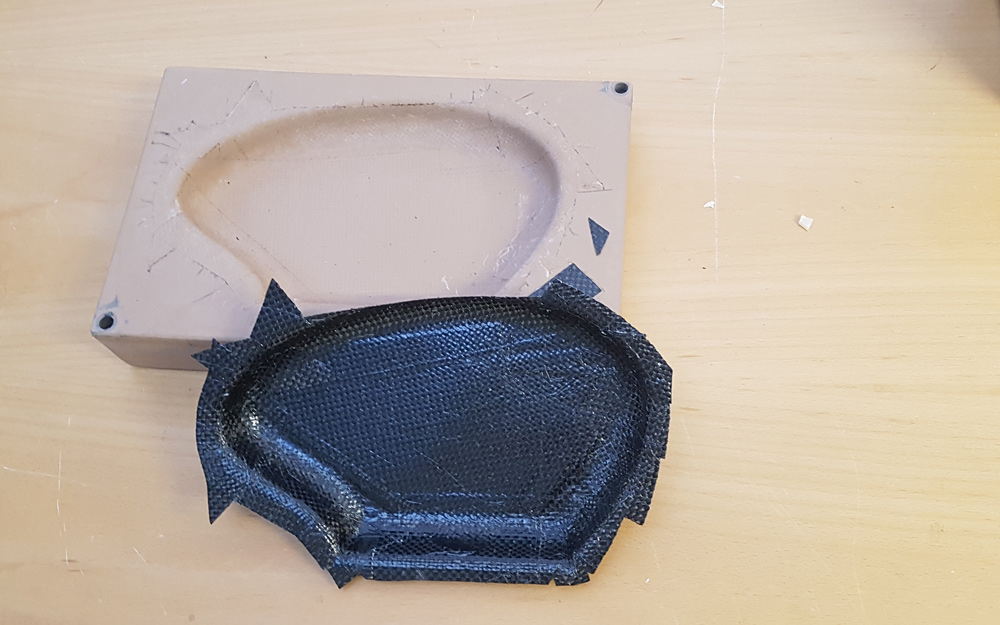

1. we calculate and produce CAD-files of the form. Eskilstuna Modellteknik is doing the milling and the mold's is taking shape. The mold's is sanded with paper and bees-waxed to fill the pores in the material.

2. A layer of preimpregnated carbon fiber is covered with a layer of woven polyester.

3. Vaccum is created with a plastic material in order to get rid of trapped air and to avoid shifting of fiber orientation during the drying process. This could have a negative impact on durability of the parts.

4. An oven is manufactured with heat gun's to heat up the air inside where the parts is baked. One crucial detail is finding the sweet spot for the temperature.

5. Finished product. Strong and light weight.